Nozzles karbén anu sementara pikeun bor bit bit sareng cone coller coller dina pengeboran minyak

Panjelasan

Bor b bsJalan bit bitler bit pétak ieu umumna dianggo dina bururkeun minyak sareng industri ngeboran gearge sareng liang cai di aranjeunna nozides karbida. Nanozzles karbén cementBakal utamina diterapkeun ka boror PDC bit sareng tumpogkeun bit roller pikeun lempeng, labu sareng naroring bor anu lega, sareng geter sareng swringing séhat.

Jenis nozzles karbid

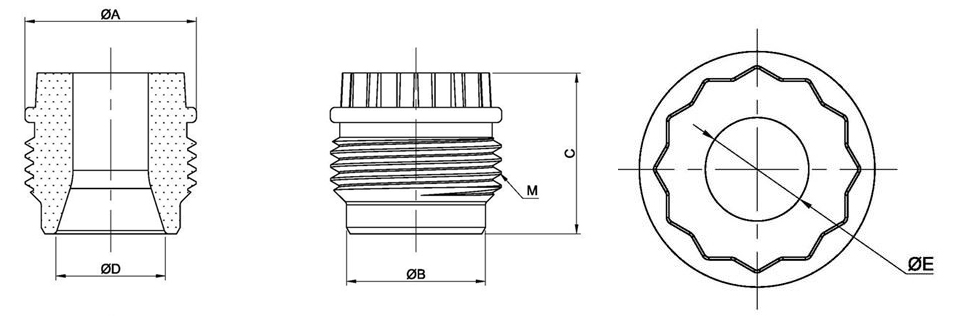

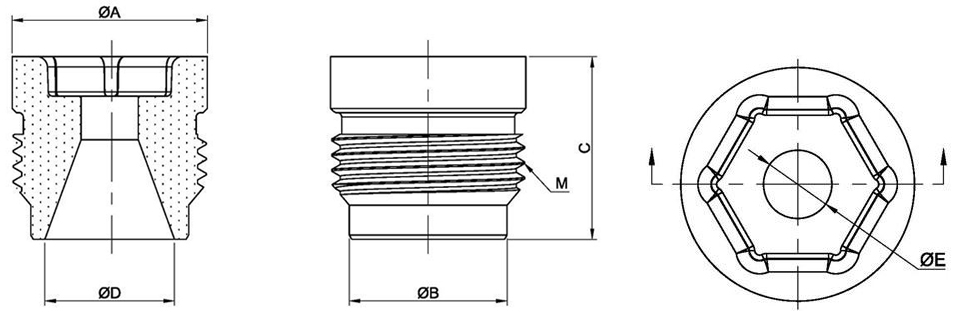

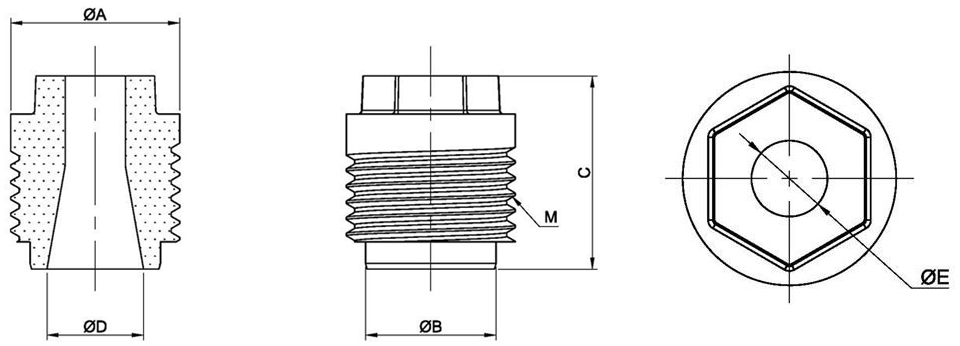

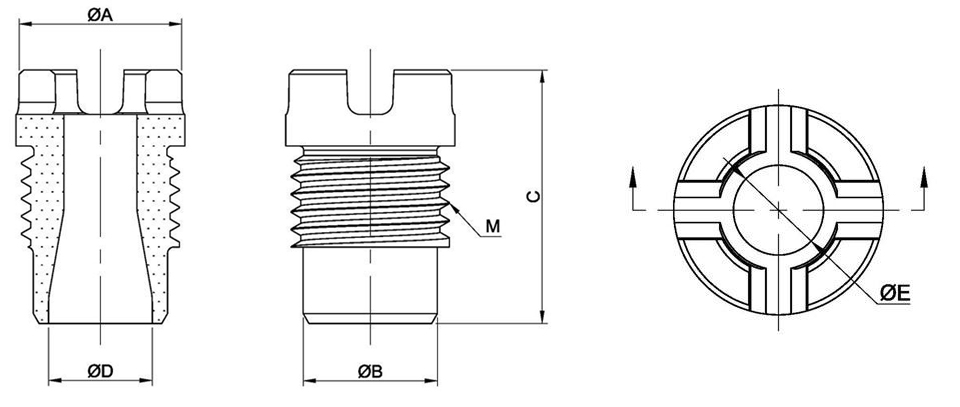

Aya dua jinis utamanozzles karbidpikeun bor bit. Hiji nyaéta nganggo benang, sareng anu sanésna tanpa benang. Nozzy taun tanpa benang anu dipaké dina lit anu roller, nozide zkzids sareng bentang kalolobaanana dina bor pdc. Numutkeun rengkuh Alat Tangan anu sanés, aya6 jinis nozzles benang pikeun bit PDC:

1. Cross grite greoves

2. Black Plum

3. Nozzles threxal luar

4. Nozzles benang héksagon internal

5. Y tip (3 slot / alur) nozchles

6. Gear roda bor

Kami moal ngan ukur ngahasilkeun standarNozzle karpo, Kami ogé tiasa ngahasilkeun nozzles ngaropéa dumasar kana gambar atanapi conto.

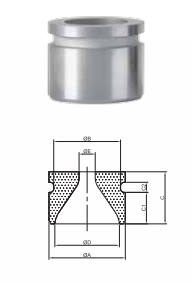

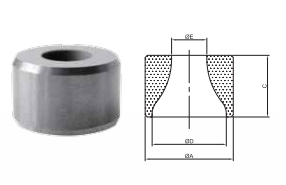

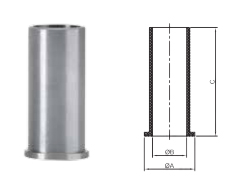

Nozzle carbide cemented pikeun concer roler roller:

Natungstennozzle kartrosmangrupikeun salah komponén pentingTumpang Roloksaeutiks, Creadzzle cerbuncle karompida divur ka siram, seese sareng melak tip anu pemotong daun burping, cair luhur ditamalkeun batu.Nozzles karbidogé ngagaduhan pangaruh rempah hidrulik. Éta tiasa ngahasilkeun distribusi tekanan samématna dina batu permukaan.AS anu langkung pemilihan nozer anu maju kanggo Roller Stors Conge, kami nawiskeun sagala jinis jinis sareng aplikasi ngebon sareng nyetél aplikasi pikeun aplikasi anu paling direbukan. Nozasi konvensional cylindrice.grades dirarancang pikeun korosi anu alus teuing atanapi résistansi érosi.Nozzles custalbisa disayogikeun kana létisan sareng sarat kelas ti para nasabah.

| Stok teu | Ø | Ø | C | C1 | C2 | Ø | Ea |

| Zzcr002301 | 18.9 | 16.3 | 18.8 | 11.9 | 4.0 | 14.7 | 6,4 |

| Zzcr002302 | 22.1 | 18.8 | 18.8 | 11.9 | 4.0 | 17,5 | 5.5 |

| Zzcr0023033 | 30.0 | 26,3 | 20.6 | 12.4 | 4.0 | 25.4 | 7.1 |

| Zzcr002304 | 33.2 | 29.9 | 27.0 | 19.1 | 4.0 | 28.6 | 7.9 |

| Zzcr002305 | 37.8 | 34.2 | 28.6 | 20,5 | 4.0 | 33,3 | 25.4 |

| Stok teu | Ø | Ø | ØB1 | C | C1 | C2 | Ø | Ea |

| Zzcr002306 | 30.0 | 22.9 | 26,3 | 46.0 | 12.4 | 4.0 | 25.4 | 7.1 |

| Zzcr00230601 | 30.0 | 22.9 | 26,3 | 46.0 | 12.4 | 4.0 | 25.4 | 11.1 |

| Zzcr002307 | 33.2 | 21.6 | 29.9 | 61.9 | 19.1 | 4.0 | 28.6 | 7.1 |

| Zzcr00230701 | 33.2 | 21.6 | 29.9 | 61.9 | 19.1 | 4.0 | 28.6 | 10,3 |

| Zzcr002308 | 37.8 | 26.2 | 34.2 | 66.7 | 20,5 | 4.0 | 33,3 | 15,9 |

| Zzcr00230801 | 37.8 | 26.2 | 34.2 | 66.7 | 20,5 | 4.0 | 33,3 | 8.0 |

| Zzcr00230802 | 37.8 | 26.2 | 34.2 | 66.7 | 20,5 | 4.0 | 33,3 | 11.9 |

| Stok teu | Ø | C | Ø | Ea |

| Zzcr002309 | 31.8 | 22.2 | 26.7 | 9,5 |

| Zzcr002010 | 20.3 | 12.6 | 15.2 | 14,3 |

| Zzcr002311 | 20.4 | 12.7 | 15,9 | 9,3 |

| Stok teu | Ø | Ø | C | C1 | Ø | Ea |

| Zzcr002312 | 33.20 | 28.45 | 42.85 | 26.98 | 28.58 | 7.9 |

| Zzcr002313 | 33.20 | 28.45 | 42.85 | 26.98 | 28.58 | 9,5 |

| Zzcr002314 | 33.20 | 28.45 | 42.85 | 26.98 | 28.58 | 11.4 |

| Zzcr002315 | 33.20 | 28.45 | 42.85 | 26.98 | 28.58 | 14,5 |

| Zzcr002316 | 33.20 | 28.45 | 42.85 | 26.98 | 28.58 | 17,5 |

| Stok teu | Ø | Ø | C | C1 | Ø | Ea |

| Zzcr002317 | 26.8 | 19.7 | 35,7 | 19.1 | 22.2 | 6,4 |

| Zzcr002318 | 33.2 | 28.4 | 42.9 | 27 | 28.6 | 7.9 |

| Zzcr002319 | 33.2 | 28.4 | 42.9 | 27 | 28.6 | 10,3 |

| Zzcr002220 | 33.2 | 28.4 | 42.9 | 27 | 28.6 | 14,3 |

| Zzcr002321 | 33.2 | 28.4 | 42.9 | 27 | 28.6 | 19.1 |

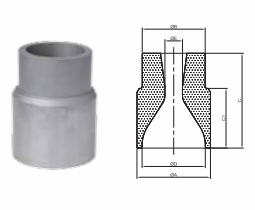

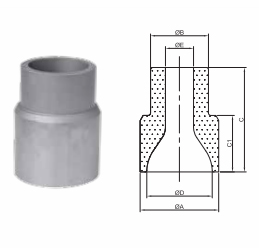

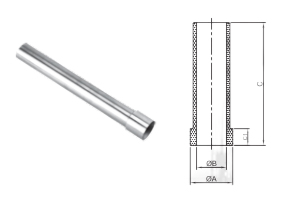

Nozzles karbén cement pikeun bor b bs:

Nozzles karbén cementedutamana dianggo pikeunBor b bspikeun siram, cutlege cutle sareng lega. Samentara éta, cairan tekanan tinggi dibungkus tina nada cozzes bakal ngabantosan ngarobih batu.

Salaku supplier integral lengkep, urang nyayogikeunnozchlesPikeun bor bor b cil dina rupa-rupa stakses sareng ukuran kombinasi pikeun ngabebaskeun aplikasi Mesing handap. Watak nozzles tuturkeun pikeun PDC dirarancang pikeun korosi anu pikaresepeun pisan sareng résistansi ESosi.Nozzlesbisa dilakukeun kana gambar sareng sarat kelas ti para nasabah.

Nozle threzle séri badai parut

| Stok teu | Ø | Ø | C | Ø | Ea | M |

| Zzcr002222 | 27.1 | 21.9 | 25.4 | 17,5 | 5.6 | 1-1 / 16-12un-2a |

| Zzcr002323 | 27.1 | 21.9 | 25.4 | 17,5 | 7.1 | 1-1 / 16-12un-2a |

| Zzcr002324 | 27.1 | 21.9 | 25.4 | 17,5 | 8.7 | 1-1 / 16-12un-2a |

| Zzcr002325 | 27.1 | 21.9 | 25.4 | 17,5 | 11.9 | 1-1 / 16-12un-2a |

| Zzcr002326 | 27.1 | 21.9 | 25.4 | 17,5 | 15,9 | 1-1 / 16-12un-2a |

Noze bread tina séri badag hexagon:

| Stok teu | Ø | Ø | C | Ø | Ea | M |

| Zzcr00237 | 27.1 | 21.9 | 25.4 | 18 | 6,4 | 1 '' - 1 / 16-12un-2a |

| Zzcr002228 | 27.1 | 21.9 | 25.4 | 18 | 7.9 | 1 '' - 1 / 16-12un-2a |

| Zzcr002229 | 27.1 | 21.9 | 25.4 | 18 | 12.7 | 1 '' - 1 / 16-12un-2a |

| Zzcr00230 | 27.1 | 21.9 | 25.4 | 18 | 15,9 | 1 '' - 1 / 16-12un-2a |

| Zzcr00231 | 19.1 | 16.1 | 23 | 13 | 6,4 | 3/4 '' - 12UN-2A |

| Zzcr002322 | 19.1 | 16.1 | 23 | 13 | 7.1 | 3/4 '' - 12UN-2A |

| Zzcr002333 | 19.1 | 16.1 | 23 | 13 | 7.9 | 3/4 '' - 12UN-2A |

| Zzcr002334 | 19.1 | 16.1 | 23 | 13 | 9,5 | 3/4 '' - 12UN-2A |

| Zzcr00235 | 19.1 | 16.1 | 23 | 13 | 11.1 | 3/4 '' - 12UN-2A |

Threzle breadze séri rengkuh héksagon jero:

| Stok teu | Ø | C | Ea | M |

| Zzcr002336 | 25.4 | 28.6 | 7.1 | 1 "-14uns-2a |

| Zzcr00237 | 25.4 | 28.6 | 15,9 | 1 "-14uns-2a |

| Zzcr00238 | 25.4 | 28.6 | 18.6 | 1 "-14uns-2a |

Nozzle bitah séri Tople Top:

| Stok teu | Ø | Ø | C | Ø | Ea | M |

| Zzcr00239 | 20.3 | 16.1 | 30,5 | 12,5 | 5.6 | 3/4 '' - 12UN-2A |

| Zzcr002340 | 20.3 | 16.1 | 30,5 | 12,5 | 6,4 | 3/4 '' - 12UN-2A |

| Zzcr002341 | 20.3 | 16.1 | 30,5 | 12,5 | 7.1 | 3/4 '' - 12UN-2A |

| Zzcr002342 | 20.3 | 16.1 | 30,5 | 12,5 | 9,5 | 3/4 '' - 12UN-2A |

| Zzcr002343 | 20.3 | 16.1 | 30,5 | 12,5 | 10,3 | 3/4 '' - 12UN-2A |

| Zzcr002444 | 20.3 | 16.1 | 30,5 | 12,5 | 11.1 | 3/4 '' - 12UN-2A |

| Zzcr002345 | 20.3 | 16.1 | 30,5 | 12,5 | 11.9 | 3/4 '' - 12UN-2A |

| Zzcr002346 | 20.3 | 16.1 | 30,5 | 12,5 | 12.7 | 3/4 '' - 12UN-2A |

Jaket liang nozzle:

| Stok teu | Ø | Ø | C |

| Zzcr002347 | 28.5 | 22.0 | 40 |

| Zzcr002348 | 28.5 | 22.0 | 70 |

| Zzcr002349 | 24.6 | 18.0 | 50 |

| Zzcr002050 | 22.9 | 18.0 | 35 |

| Zzcr002351 | 16,5 | 11,5 | 40 |

| Stok teu | Ø | Ø | C | C1 |

| Zzcr002352 | 17.0 | 11.1 | 76 | 9,5 |

| Zzcr002353 | 24.2 | 17,5 | 40 | 9,5 |

| Zzcr002354 | 24.2 | 17,5 | 50 | 9,5 |

| Zzcr002555 | 24.2 | 17,5 | 80 | 9,5 |

| Zzcr002356 | 24.2 | 17,5 | 95 | 9,5 |

Pendaptaran kelas

Kompokan sasmita khusus pikeun kabutuhan jadb tamba pikeun PDC Bits. Rincian sababaraha sasmita sapertos kieu:

| Sasmah | Pasipatan fisik | Aplikasi utama sareng ciri | ||

| Gangguan susuk | Perténaran | Trs | ||

| H higa | g / cm3 | N / mm2 | ||

| C35 | 88.5-89.5 | 14.30-14.50 | ≥2800 | Éta cocog pikeun ngahasilkeun nozzles benang kusabab hardness tinggi sareng gaya anu saé. |

| Cr25 | 88.7-89.7 | 14.20-14.50 | ≥3000 | Éta cocog pikeun ngahasilkeun cakes tinggi, muncung bengkokan anu dianggo dina minyak minyak & gas sareng industri sareng pangaruh anu bertitan-luhur sareng diwangun ku résistansi. |

Kauntungan urang

● Séri anu lengkep pikeun nozzles pikeun roller cengkéh concl

● Korsicrosion anu saé

● 100% bahan atah aslina

● Pangiriman gancang 3 ~ 5 minggu

● ukuran precision anu luhur dikawasa

● nozzle kustomisasi ditampi

Jasa urang

● Pamariksaan bahan sareng persetujuan

● Pamariksaan diménsi sareng persetujuan

● Sampel jasa analisa kelas anu sayogi

● OEM sareng Odm ditampi

● Evaluasi kelas rinci

● jasa métallurgis

Paleuran produksi

Grinding baseuh

Semprot

Pencét

Tpa pencét

Semi-pencét

Hun dosa

Peralatan Ngolah

Breingan

Motong kawat

Ngagiling nangtung

Ngilu universal

Pesawat ngagiling

Mesin Milling CNC

Alat inspeksi

Hardness meter

Plusimér

Ukuran unsur quadratic

Alat Magnett Magnett

Mikropon logam