Tongsten Tongtide Carbidical

Panjelasan

Sajat spherik Carbide sacara jelas dipaké dina permukaan salju beba pikeun ngumbah minyak sareng salju katutup. Nyabut. Salaku tambahan ,❍ Hoktridsi karbida dikurangan ogé tiasa dianggo dina alat ngagentos sareng mesin penctahan jalan sareng sababaraha peran melunca. Huntu bal carbide.

Lamaran

Tombol Carbide Semement sacara jauh dipaké dina pengeboran minyak sareng salju dibagi, salju berlublatis atanapi alat-alat anu sanésna sanés. Numutkeun mesin kerén anu béda-béda, sapertos cut conge, gugus dth goring géologis, tina wadah bola bal anu ageung dibagi ku sisina standar, posisi bal. Stabilitas sareng téknologi luhur mastikeun kualitas luhureun produk kami, huntu bes terer sering dianggo salaku alat ngeben, alat mesin musik min sareng alat pangropéa nganggo salju sareng spésifik di salju. Suku bal karbohideu ogé dianggo kalayan alat anu anver dina quarrying, pertambangan di torowongan sareng gedong sipil. Salaku tambahan, ogé dianggo salaku rada pas pikeun kerja karasa anu beurat atanapi jero alat bor anu jero-jalan pas.

Fitur

Carbide carbide mangrupikeun bahan pangsaéna pikeun ngahasilkeun huntu bola bola centeri anu ageung dianggo dina industri pengeboran anu DHA.

Tombol Carbida loba dianggo dina pertambangan, kuut sareng motong kusabab karasaeun luhur. Éta ogé tiasa dianggo dina bit pangirian beurat.

Kelas

| Kelas | Perténarang / cm3 | Trs mpa | Gangguan susukH higa | Lamaran |

| C4c | 15.10 | 1800 | 90.0 | Utamina dianggo pikeun motong bahan susah sareng lemes tina bor dampak. |

| Cik | 14.95 | 1900 | 90,5 | Dipaké salaku bit bara bara |

| Cron | 14.80 | 2200 | 89.5 | Dipaké janten borons inti, luhureun batat listrik, batub roub, peti-conce cords sareng scrers corak laut. |

| Crosc | 14.80 | 2400 | 88.5 | Utamana dipaké salaku cangkang bal warna sedeng sareng alit sareng janten bushing rungkun eksplorasi rotarasi. |

| Cr11c | 14.40 | 2700 | 86.5 | Lolobana dianggo di dampak dampak sareng di concs ngabebur pikeun motong huntu bes tina bahan bakar. |

| Cr13c | 14.2 | 2850 | 86.5 | utamina dianggo pikeun motong léh tina bahan sedeng sareng tinggi dina borongan dampak. |

| Cr15c | 14.0 | 3000 | 85.5 | Anggo kanggo kulit kerucingan minyak sareng méter sareng sedeng rok toyal batu. |

Ukuran

OEM ditampi.

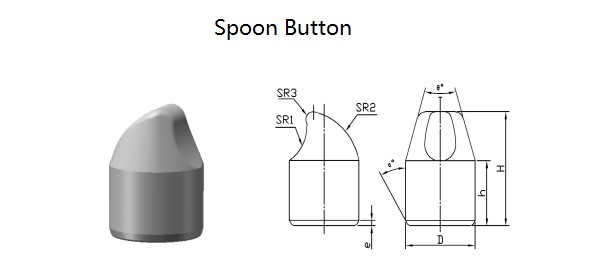

Ukuran standar tombol Carbide Tungsten sapertos di handap:

| Ngetik | Diménsi (mm) | ||||||||

| D | H | h | Ɵ ° | Sr1 | Sr2 | Sr3 | ° | e | |

| S1015 | 10.25 | 15 | 9.8 | 50 | 12 | 20 | 3 | 18 | 1.2 |

| S1116 | 11.3 | 16,5 | 10.2 | 50 | 15 | 24 | 3 | 18 | 1.2 |

| S1218 | 12.35 | 18 | 11 | 36 | 20 | 25 | 2,5 | 18 | 1,5 |

| S1319 | 13.35 | 19 | 12 | 50 | 15 | 20 | 3 | 18 | 1,5 |

| S1421 | 14.35 | 21 | 12,5 | 40 | 12 | 25 | 3 | 18 | 1,8 |

| S1521 | 15.35 | 21 | 12 | 50 | 20 | 30 | 3 | 18 | 1,8 |

| S1624 | 16.35 | 24 | 13 | 30 | 15 | 20 | 3 | 18 | An 2 |

| S1827 | 18.25 | 27 | 14,5 | 30 | 18 | 20 | 3 | 18 | An 2 |

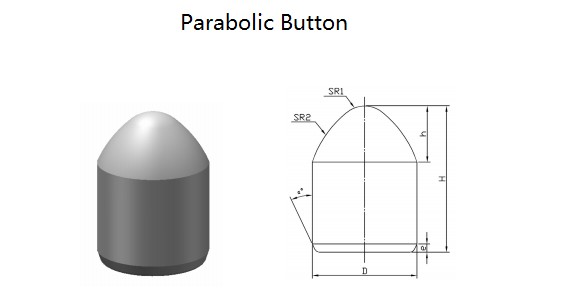

| Ngetik | Diménsi (mm) | |||||||

| D | H | Sr1 | Sr2 | h | ° | ° | e | |

| D0711 | 7.25 | 11 | 1,9 | 8.7 | 3.9 | 20 | 25 | 1,6 |

| D0812 | 8.25 | 12 | 2,5 | 9 | 4,5 | 20 | 25 | 1,6 |

| D0913 | 9.25 | 13 | 2,5 | 11 | Tipi 5 | 20 | 25 | 1,8 |

| D1015 | 10.25 | 15 | 3.2 | 11.8 | Tipi 5 | 20 | 25 | 1,8 |

| D1117 | 11.3 | 17 | 3 | 13,5 | Kelas 6 | 20 | 25 | 1,8 |

| D1218 | 12.35 | 18 | 3 | 12 | 6,5 | 20 | 20 | An 2 |

| D1319 | 13.35 | 19 | 3,5 | 13,5 | 7.1 | 20 | 20 | An 2 |

| D1420 | 14.35 | 20 | 4.2 | 13 | 8 | 20 | 20 | An 2 |

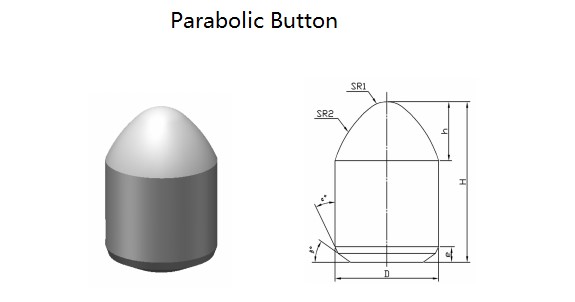

| Ngetik | Diménsi (mm) | ||||||

| D | H | Sr1 | Sr2 | h | ° | e | |

| D0711a | 7.25 | 11.0 | 1,9 | 8.7 | 3.9 | 18 | Panon kentang. |

| D0812A | 8.25 | 12.0 | 2,5 | 9 | 4,5 | 18 | Panon kentang. |

| D0913A | 9.25 | 13.0 | 2,5 | 11 | Tipi 5 | 18 | Panon kentang. |

| D1015A | 10.25 | 15.0 | 3.2 | 11.8 | Tipi 5 | 18 | 1.2 |

| D1117A | 11.3 | 17.0 | 3 | 13,5 | Kelas 6 | 18 | 1.2 |

| D1218a | 12.35 | 18.0 | 3 | 12 | 6,5 | 18 | 1,5 |

| D1319a | 13.35 | 19.0 | 3,5 | 13,5 | 7.1 | 18 | 1,5 |

| D1420A | 14.35 | 20.0 | 4.2 | 13 | 8 | 18 | 8 |

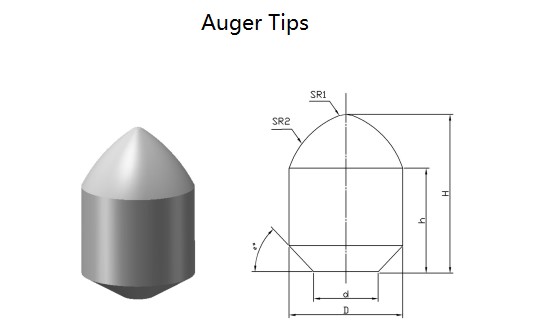

| Ngetik | Diménsi (mm) | |||||

| D | d | H | h | Sr1 | Sr2 | |

| JM12222 | 12 | 3.0 | 22 | 15 | 1,5 | 26 |

| JM1425 | 14 | 4.0 | 25 | 17 | 1,5 | 26 |

| JM1625 | 16 | 5.0 | 25 | 16 | 1,5 | 26 |

| JM1828 | 18 | 5.0 | 28 | 18 | 1,5 | 26 |

| JM2428 | 24 | 10.1 | 28 | 16 | An 2 | 36 |

| JM2534 | 25 | 18.0 | 34 | 20 | - | 25 |

| Ngetik | Diménsi (mm) | |||||

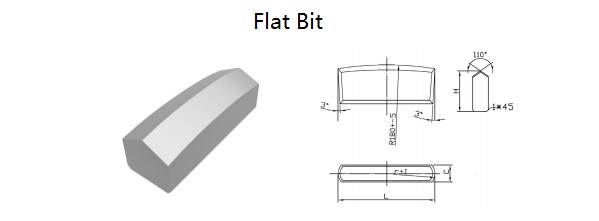

| L | H | C | r | |||

| A | B | C | ||||

| K026 | 26 | 18.0 | 15 | 12,5 | 8 | 13 |

| K028 | 28 | 18.0 | 15 | 12,5 | 8 | 14 |

| K030 | 30 | 18.0 | 15 | 12,5 | 8 | 15 |

| K032 | 32 | 18.0 | 15 | 12,5 | 8 | 16 |

| K034 | 34 | 18.0 | 15 | 12,5 | 8 | 17 |

| K036 | 36 | 18.0 | 15 | 12,5 | 10 | 18 |

| K038 | 38 | 18.0 | 15 | 12,5 | 10 | 19 |

| K040 | 40 | 18.0 | 15 | 12,5 | 10 | 20 |

| K042 | 42 | 18.0 | 15 | 12,5 | 10 | 21 |

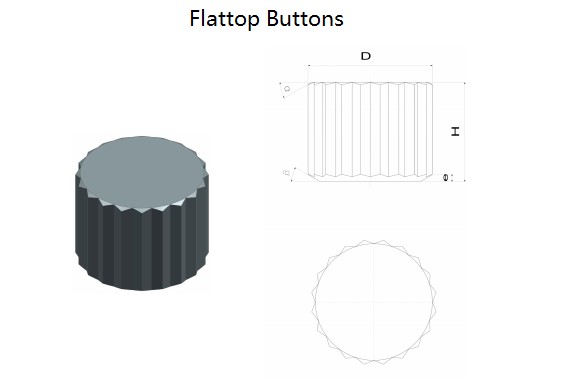

| Ngetik | Diménsi (mm) | ||||

| D | H | t | ° | e | |

| MH0806 | 8 | 6,0 | 0,5 | 25 | 1.1 |

| MH1008 | 10 | 8.0 | 0,5 | 25 | 1,9 |

| MH1206 | 12 | 6,0 | 0,5 | 25 | 1,9 |

| MH1208 | 12 | 8.0 | 0,5 | 25 | 2,5 |

| MH1410 | 14 | 10.0 | 0,5 | 25 | 2,5 |

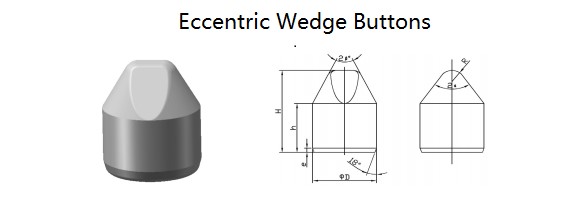

| Ngetik | Diménsi (mm) | |||||||

| D | H | h | R | r | ° | ° | e | |

| X0810 | 8 | 10 | 6,5 | An 2 | 1,8 | 45 | 22,5 | 1,5 |

| X1011 | 10 | 11 | 7 | 2,5 | An 2 | 45 | 22,5 | 1,5 |

| X1013 | 10 | 13 | 9 | 2,5 | An 2 | 45 | 22,5 | 1,5 |

| X1115 | 11 | 15 | 8 | 2.8 | 2,5 | 22,5 | 22,5 | 1,5 |

| X1215 | 12 | 15 | 9 | 3 | 2,5 | 45 | 22,5 | 1,5 |

| X1217 | 12 | 17 | 10,5 | 3,5 | 3 | 35 | 20 | 1,5 |

| X1418 | 14 | 18 | 10 | 3,5 | 3 | 45 | 22,5 | 1,5 |

| X1420 | 14 | 20 | 11 | 2.7 | 3 | 35 | 22,5 | 1,5 |

| X1520 | 15 | 20 | 12 | 3 | 3 | 40 | 22,5 | 1,5 |

| X1621 | 16 | 21 | 11 | 2,6 | 3 | 35 | 22,5 | An 2 |

| X1623 | 16 | 23 | 12 | 3 | 3,5 | 30 | 18 | An 2 |

| X1721 | 17 | 21 | 13 | Bageud | 3,5 | 40 | 22,5 | An 2 |

| X1724 | 17 | 24 | 13 | 3,5 | 3,5 | 30 | 22,5 | An 2 |

| X1929 | 19 | 29 | 17 | Bageud | 3 | 30 | 15 | An 2 |

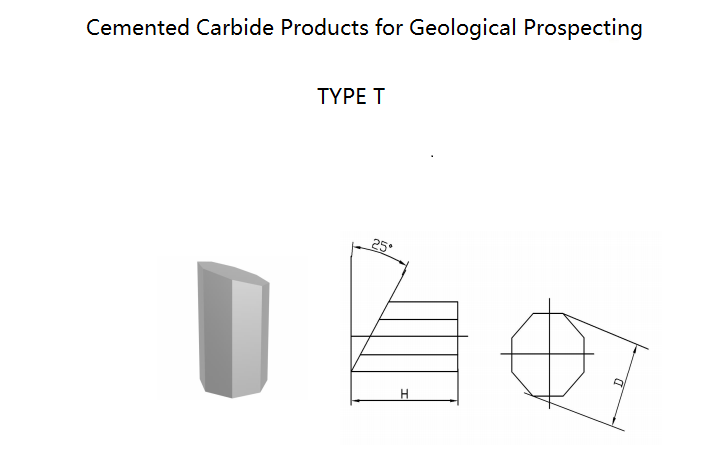

| Ngetik | Diménsi (mm) | |

| D | H | |

| T105 | Tipi 5 | 10 |

| T106 | 7 | 10 |

| T107 | 7 | 15 |

| T109 | 9 | 12 |

| T110 | 10 | 16 |

Kauntungan urang

Kecap karbida anu tiasa tahan kana ngagem résistansi sareng dampak hanjakalna, sareng ngagaduhan laju ngering anu langkung luhur ti produk anu sami. The non-grinding life of the bit is about 5-6 times as long as that of the bit with the same diameter, which is beneficial to saving auxiliary working hours, reducing manual labor and speeding up engineering speed.

Pikeun langkung retén, ngabalikeun hubungan kami dina iraha waé!

Paleuran produksi

Grinding baseuh

Semprot

Pencét

Tpa pencét

Semi-pencét

Hun dosa

Peralatan Ngolah

Breingan

Motong kawat

Ngagiling nangtung

Ngilu universal

Pesawat ngagiling

Mesin Milling CNC

Alat inspeksi

Hardness meter

Plusimér

Ukuran unsur quadratic

Alat Magnett Magnett

Mikropon logam